Gurley Model 4340 Automatic Densometer & Smoothness Tester

Combination of low, standard and high pressure Gurley Densometers and smoothness testers

Our flagship instrument. The Model 4340 combines the abilities of our textile, standard and high pressure Densometers, S-P-S Testers as well as our programmable digital timers and provides a reading in seconds, thus reducing the time required to test a material. By utilizing state-of-the-art mass flow technology, the Model 4340 can accurately test both low and high flow materials traditionally tested between 0 and 50,000 'Gurley Seconds'. At the end of either an automatic or manual test, the user can then toggle between Gurley units, Bendtsen, Sheffield or Bekk equivalent units. Conform to TAPPI T-460 & TAPPI T-536-88, ASTM D-726-58 & D-202-77, APPITA/AS 1301-420, BS 5926, CPPA D-14, ISO 5636/5, SCAN P-19 & P-53.

Overview

The Model 4340 differs from the traditional manual Densometers in several ways. First, the Model 4340 utilizes the latest mass flow and servo-regulator technology to provide a quick, accurate test that is oil-free. Second, pneumatic cylinders insure both a consistent clamping pressure as well as an automatic test feature; which allows the user to test a sample several times without constantly opening and closing the test area by hand. Third, with the addition of an auto-drive mechanism, the user can program the number tests as well as the span they are tested over. Therefore, a sheet or strip of paper can be analyzed automatically, with output in either Gurley seconds, Sheffield, Bendsten or Bekk equivalent seconds.

By utilizing several state-of-the-art mass flowmeters, in addition to a servo-regulator, the Model 4340 can accurately test both low and high flow materials that have traditionally tested between 0 and 50,000 'Gurley Seconds'. A typical test involves the Model 4340 automatically choosing the optimum test pressure (called 'AUTO-SELECT') based on the amount of flow recorded on the corresponding flowmeter and then displaying the test time. At the end of each manual test, the user can toggle between either Gurley units, Bendsten, Sheffield or Bekk equivalent units. If an automatic test was chosen, the user can toggle between alternate equivalent units, after the mean and standard deviation has been calculated and displayed.

If desired, the user can predetermine the units they want displayed (called 'USER-DEFINED'). This feature allows the user to directly compare his or her older manual unit with the results achieved with the Model 4340, even though their particular material would typically test at a different pressure and provide different Gurley values (e.g. standard 'Gurley Seconds' vs. high pressure seconds). Please refer to 'TEST TYPE SETTINGS' for more information.

Applications include:

In manufacturing and printing, to control the selection of materials affording the appropriate degree of liquid (ink, varnish, sizing) absorption.

Testing filters, porous bags & materials where controlled porosity is essential.

Testing insulating materials for air resistance.

As a supplement to other physical tests enabling regulation or strength of manufacturing process to give the desired formation, appearance or strength since there is a close correlation in a given material between air permeability and these other properties.

Requirements

In order for the Model 4340 Automatic Densometer to work properly, one needs the following:

'Shop-air' or an air-compressor with a minimum of 60 PSI output.

A filter/regulator/desiccant combo which cleans, controls and dries the air so not to damage the instrument (made available by Gurley.)

110 or 220 VAC power source (Note: A universal power supply is standard in every Model 4340.)

Options

Compressor and air filter/regulator/dryer combo

Printer, dot matrix, roll feed

Interchangeable orifices (1.0 standard, 0.25 and 0.10 sq in optional)

Specifications

Dimensions: 15.75" long x 12.5" high x 9.25" wide

Weight: 60# (27kg)

Internal power supply (110-220 VAC)

Requires at least 60 PSI

Gurley Standard and Low Pressure Manual Densometers

Densometers are the accepted standard for measuring the porosity of materials such as papers, wovens, plastics and membranes. All Densometers measure the time required for a given volume and of air (25cc to 400cc) to flow through a standard area of material being tested under light uniform pressure. Certain models, such as the S-P-S Tester, are also used to measure surface smoothness and material softness. Manual and automatic units available. Conform to TAPPI T-460, ASTM D-726-58 & APPITA/AS 1301-420, BS 5926, CPPA D-14, ISO 5636/5, D-202-77, SCAN P-19 & P-53.

Specifications

The Densometer test measures the time required for a given volume of air (25cc to 300cc) to flow through a standard area of material tested, under light uniform pressure. The air pressure is supplied by an inner cylinder of specific diameter and standardized weight, floating freely within an outer cylinder partly filled with oil to act as an air-seal. The sample material is held between clamping plates having a circular orifice area of 1.0 (standard), 0.25 or 0.1 square inch (optional).

Densometer readings may be evaluated on both a direct or indirect basis dependent upon the material and test purpose. They are a direct test of materials which are intended to either resist or permit the passage of air. Indirectly, they are used to measure other physical properties which affect the flow of air through a porous sheet.

Applications include:

In manufacturing and printing, to control the selection of materials affording the appropriate degree of liquid (ink, varnish, sizing) absorption.

To test filters, porous bags & materials where controlled porosity is essential.

To test insulating materials for air resistance.

To supplement other physical tests enabling regulation or strength of manufacturing process to give the desired formation, appearance or strength since there is a close correlation in a given material between air permeability and these other properties.

Model 4110N GENUINE GURLEY Densometer

The most popular Densometer sold for measuring porosity and air permeability in materials of average values. With options such as smaller orifice plates, materials of lower permeability may be effectively tested. By using a 5 oz. cylinder, materials of a higher permeability can be tested (Model 4118).

The Model 4110 includes a 20 oz. cylinder and 1.0 square inch orifice lower clamp plate and upper adapter. The 20 oz. cylinder is graduated to 25cc for the first two spaces and 50cc for each space thereafter, for a total of 300cc. Typical of all new-style densometers, clamping pressure is supplied by turning a knob which raises and locks the lower lifting assembly and clamp plate. Both the automatic timer and instrument base are recommended with these densometers and are ordered separately.

Model 4118N GENUINE GURLEY Densometer

The Model 4118 is a Model 4110 with a 5 oz. cylinder in place of the 20 oz. inner cylinder and 0.1 sq. in. clamp and adapter plates instead of the 1.0. It is used to test fabrics and other more permeable materials for porosity, permeability and air-resistance.

In cases where the sample being tested is still too porous for an accurate reading, the Model 4301 Permeometer would be recommended.

Model 4190N GENUINE GURLEY S-P-S Tester

- To measure smoothness, porosity and softness (or compressibility)

The No. 4190 was originally developed to test the printing quality of paper. In more recent years, its use has spread to other industries in testing or checking other material surfaces for smoothness, softness or porosity. In dealing with the printability of paper, it has been found that smoothness is the most important factor in printing quality and softness is usually secondary.

The Gurley No. 4190 S-P-S Tester measures a given air flow through the sample for porosity tests and leakage across its surface(s) for softness or smoothness tests. This is accomplished by changing a variety of adapter and clamping plates.

This model is identical to the No. 4110 and 4140 for porosity tests and their components. Additionally, it includes a 0.34 lb. weight, smoothness test clamping plate, softness test clamping plate, punch and accessory storage box. Both the automatic digital timer and instrument base are recommended and should be ordered separately.

Model 4140N GENUINE GURLEY Densometer - With weighted arm assembly

This model is identical in function to No. 4110 and includes the weighted arm assembly found on No. 4190. Uniform dead-weight clamping pressure for tests is supplied by the unweighted lever arm or by the addition of either 0.34 lb. (optional) or 2.0 lb. (standard) weights. These combinations produce clamping pressures of 3.2 psi, 9.6 psi and 40.5 psi respectively.

With the addition of several test plates, a paper punch. 0.34 lb. weight and storage box, the No. 4140 becomes a no. 4190. Order the digital timer and base separately.

Model 4320DN Digital Timing Attachment

The Model 4320 Programmable Digital Timer is designed specifically for all Gurley Densometers and High Pressure models. The Model 4320 not only increases the accuracy and productivity of these instruments, but provides recording and computing capabilities that will absolutely minimize the possibility of operator error. Both RS-232 and Centronics output to a variety of devices, including most printers and PC's.

Other Model 4320DN features include: Automatic & manual program options, calculates mean & standard deviation, built-in calibration program, easy to read graphic display, fits all GENUINE GURLEY Densometers, User Programmable, date/time stamp, automatic sensitivity calibration

Gurley High Pressure Densometers

Specifications

High Pressure Densometers are the accepted standard for measuring the porosity, air-permeability or air-resistance of materials having low permeability. Typical materials include coated papers, plastics and membranes. High Pressure units are recommended whenever a standard unit would yield excessive measurement times. Manual and automatic units available. Conform to TAPPI T-536-88 and ASTM D-726-58, Method B.

The densometer test measures the time required for a specific volume of air (2.5cc to 30cc), at a constant pressure of 12.2 inches W.C., to flow through a standard area of the material being tested. The air pressure is supplied by a weighted inner cylinder floating freely within an outer cylinder which is partially filled with oil to act as a seal. The sample material is held between clamping plates having a circular orifice area of 1.0 square inch (standard).

High pressure units are recommended whenever a standard unit would yield excessive measurement times. Porosity readings with the high pressure densometer are much faster than those taken with a regular densometer. This difference can be as great as twenty-five times faster since higher air pressure is used and air volumes are one-tenth those measured with a standard densometer. Readings also can be affected by using different adapter plates with smaller orifices on all models.

Conversion of Models Containing Mercury to Oil

The new oil-filled high pressure densometers replace older mercury-filled models yet feature identical performance, continued reliability and accuracy. The only difference is the physical height of the unit (27" with inner cylinder down).

Obsolete Models 4120 & 4200 contain mercury which may pose personal safety hazards. These instruments can be converted to oil by replacing the entire upper cylinder assembly. The conversion must be performed at our Troy, NY factory and includes packaging for and disposal of the mercury. Please refer to No. 4050-C Product Bulletin for details.

Model 4150N GENUINE GURLEY High Pressure Densometer

This model measures porosity and air-permeability of materials. It includes a 1.0 square inch clamping plate, adapter and porosity calibration plate. The inner cylinder is graduated to 2.5cc for the first two spaces and thereafter each 5cc for a total of 30cc. Clamping pressure is supplied by turning a knob which raises and locks the lower clamping plate. Order the automatic digital timing attachment and instrument leveling base separately.

Model 4250N GENUINE GURLEY H-P-S Tester

The No. 4250 was originally developed to test the printing quality of paper. In more recent years, its use has spread to other industries in testing or checking other material surfaces for smoothness or porosity. In dealing with the printability of paper, it has been found that smoothness is the most important factor in printing quality.

The Gurley No. 4250 H-P-S Tester measures a given air flow through the sample for porosity tests and leakage across its surface(s) for smoothness tests. This is accomplished by changing a variety of adapter and clamping plates.

This model is identical to the No. 4150 and 4240 for porosity tests and their components. Additionally, it includes a 0.34 lb. weight, smoothness test clamping plate, punch and accessory storage box. Both the automatic digital timer and instrument base are recommended and should be ordered separately.

Model 4240N GENUINE GURLEY High Pressure

Densometer with Weighted Arm Assembly

This model is identical in function to No. 4150 and includes the weighted arm assembly found on No. 4250. Uniform dead-weight clamping pressure for tests is supplied by the unweighted lever arm or by the addition of either 0.34 lb. (optional) or 2.0 lb. (standard) weights. These combinations produce clamping pressures of 3.2 psi, 9.6 psi and 40.5 psi respectively. With the addition of the smoothness test plate, a paper punch. 0.34 lb. weight and storage box, the No. 4240 becomes a no. 4250. Order the digital timer and base separately.

Digital Timing Attachment

The Model 4320 Programmable Digital Timer is designed specifically for all Gurley Densometers and High Pressure models. The Model 4320 not only increases the accuracy and productivity of these instruments, but provides recording and computing capabilities that will absolutely minimize the possibility of operator error. Both RS-232 and Centronics output to a variety of devices, including most printers and PC's.

Other Model 4320DN features include: Automatic & manual program options, calculates mean & standard deviation, built-in calibration program, easy to read graphic display, fits all Genuine GurleyTM Densometers, user programmable, date/time stamp, automatic sensitivity calibration

Helping you decide which is right for you!

The essential difference between these instruments is that the Permeometer tests materials primarily designed to allow air flow, while the Densometers typically test materials of lower permeability where air flow is a secondary characteristic. The means of instrument operation and resulting units of measure are related but stated differently. The Permeometer measures actual flow in cubic feet per minute, per square foot of material (at 0.5" W.C gage pressure drop). The Densometers measure the time required to force a known volume of air through one square inch of material (at 1.22" to 12.2" W.C. gage pressure).

Some crossover models exists for materials of "borderline porosity", in particular those which can be tested on the Model 4118 Textile Densometer (with 5 oz. cylinder) and Model 4301 Permeometer. The choice of instrument is typically based on the permeability of the sample and which device provides more useful data. Generally speaking, a Permeometer cannot be used to test ordinary papers.

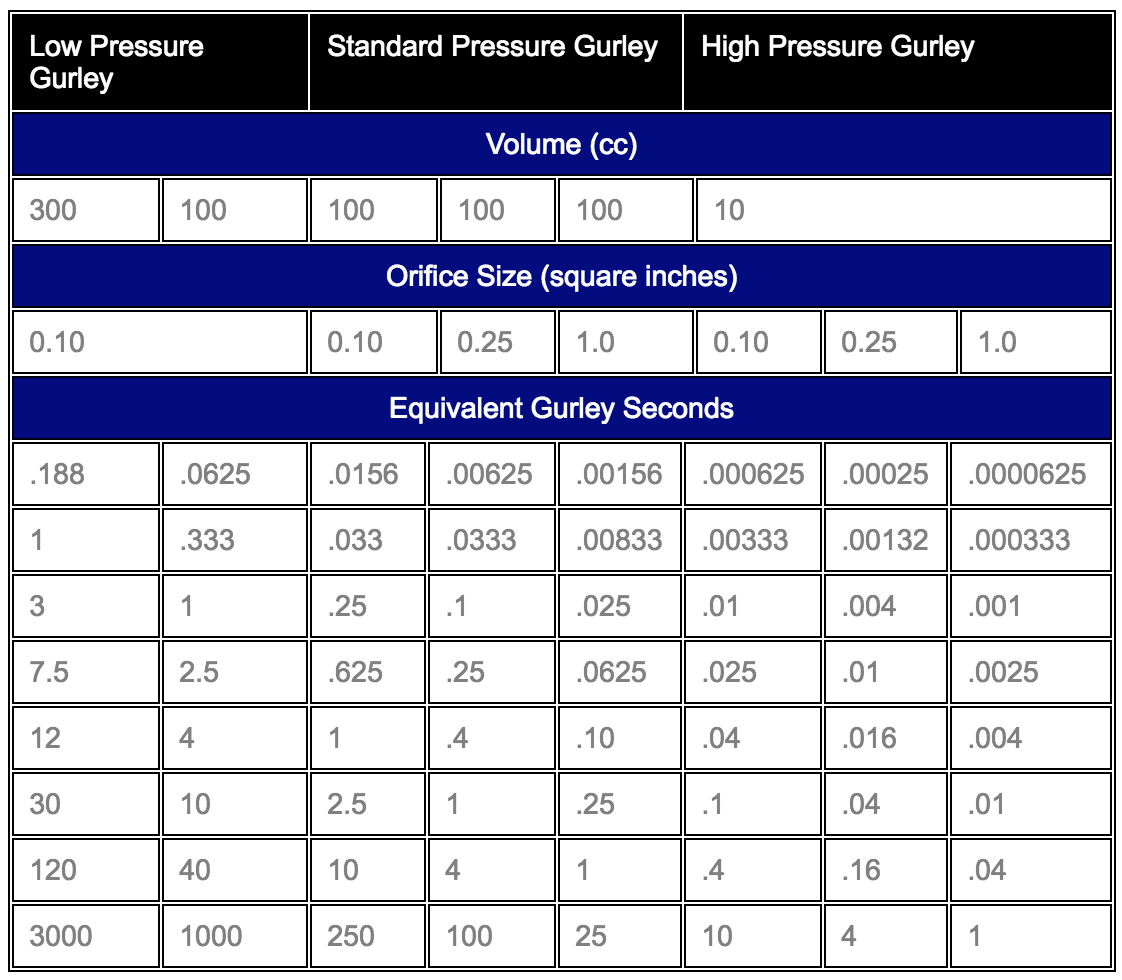

Porosity Conversions between Gurley Orifices, Test Pressures and Volumes

There exists a linear relationship between material test results for Gurley low, standard and high pressure Densometers. The benchmark for these instruments is what is commonly referred to as "Gurley Seconds", which denotes to the time needed to pass 100cc of air through 1.0 square inch of material at standard pressure. Depending on the time it takes to pass air under these conditions, a user may prefer to increase or decrease the test time (after all - who wants to wait) by increasing or decreasing the pressure and/or orifice size. For example, if a sample takes 2,500 Gurley Seconds (i.e., 100cc using 1.0 sq.in. and standard pressure) on a standard Densometer (Model 4110 or 4190), the same sample would only take 100 seconds on a high pressure Densometer (Model 4150 or 4250) using the same orifice and 10cc of air. Please refer to the following chart for more information. Note that the Model 4340 Automatic Densometer and Smoothness tester does not wait for the air to displace; the Model 4340 uses mass flow technology for instantaneous results. Still, the Model 4340 mirrors the output of all Gurley manual Densometers regardless of the orifice or volume used.